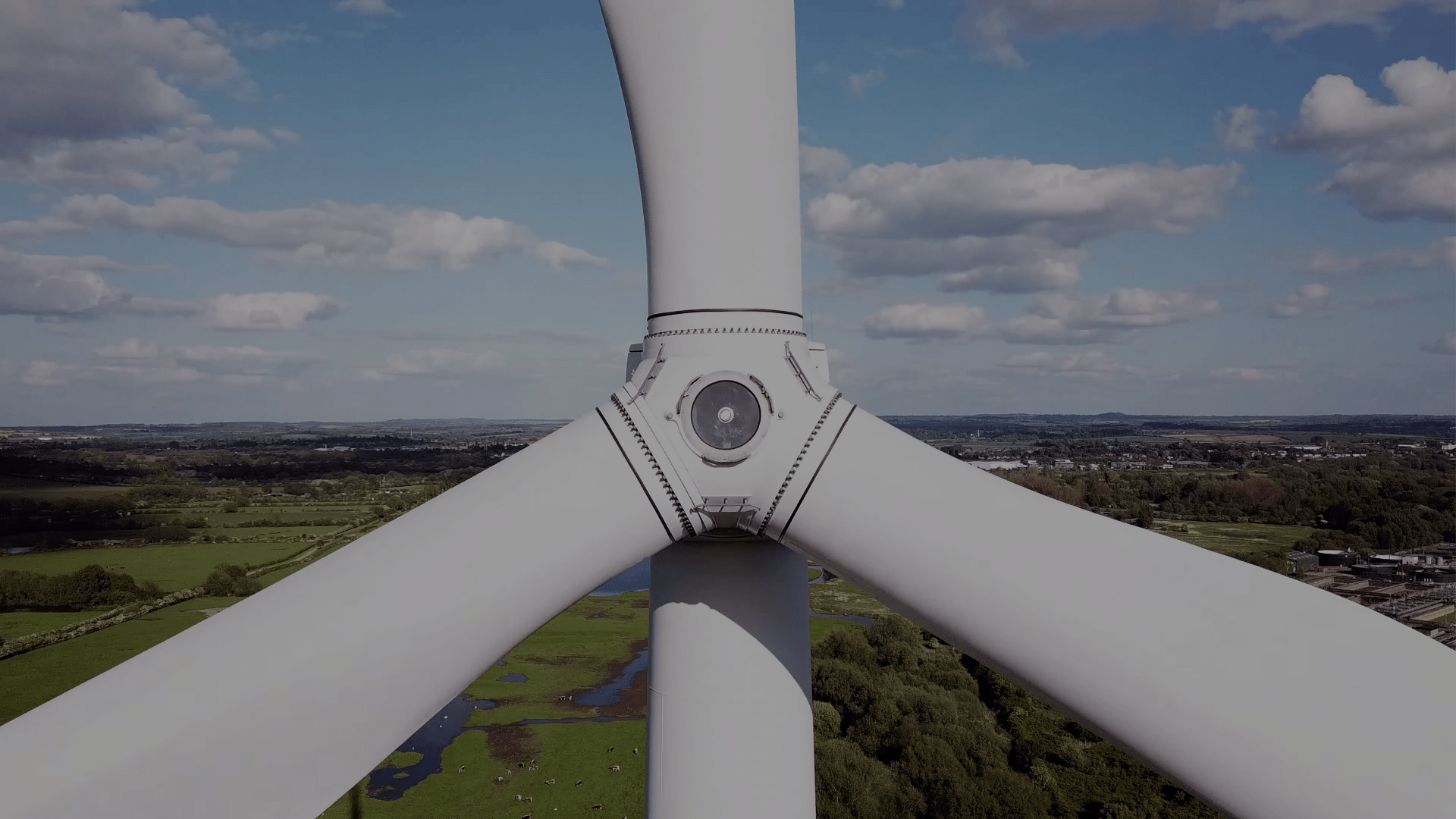

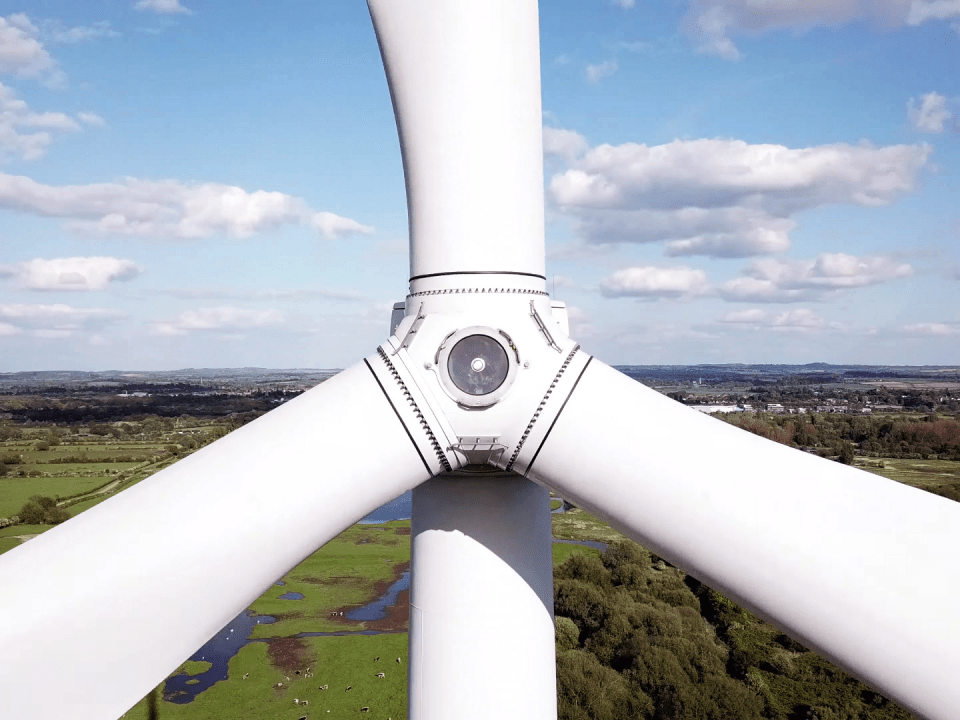

3 ways our SmartScrews help with lifetime extension of your wind turbines

18. June 2021Bremen, 30 September 2021

The joint project "Intelligent Connecting Elements in Supporting Structures and Drive Train of Wind Energy Converters", inVETra for short, started in September 2021. In the inVETra project, an innovative condition monitoring system (CMS) based on a new sensor concept is being developed for use in wind turbines. The core innovation lies on the one hand in the development of sensory connection elements and on the other hand in the development of a dynamically tracked CMS. The consortium is made up of the Ruhr University Bochum (Institute for Energy System Technology and Power Mechatronics, consortium leader), the Fraunhofer Institute for Wind Energy Systems IWES and the two industrial partners, PEINER Umformtechnik GmbH and Sensorise GmbH.

The industrial partners are largely responsible for the development of the sensor screw, which is characterised by the use of standardised screw and connecting elements as sensor carriers and is based on the invention of Dr Winkelmann (Sensorise). The project benefits from the expertise of PEINER, which is a leading supplier of fasteners for wind turbines. Conventional bolted connections will be replaced by sensor-based connections at only a few suitable measuring points in the support structures and drive trains of wind turbines, which have been identified through extensive validation. Measures to identify suitable measuring points are being carried out in the Fraunhofer IWES sub-project, using appropriate test infrastructure for full-scale wind turbine components. The large-scale test stands are suitable for the deployment and prototypical testing of the CMS to be developed and can be ideally used to test the sensor bolts in a full-scale setup with real interface components and validate them with supplementary measurement technology.

The sensor screws provide high-resolution images of the acting forces, which, in addition to direct screw monitoring, also provide conclusions about the resulting load collectives of operation-critical plant components with the help of the CMS.

In the sub-project of the Ruhr-Universität Bochum, the sensor screw-based CMS is designed, realised and tested in multi-stage validation steps together with the partners. Dynamic models of the entire plant are continuously updated and adapted on the basis of the recorded data. This provides highly dynamic observer structures to monitor the condition of the plant on the basis of the determined load collectives, to detect early failures and to estimate the remaining service life.

Großlagerprüfstand BEAT6.1 des Fraunhofer IWES - Ulrich Perrey

Das Vorhaben wird mit Mitteln des Bundesministeriums für Wirtschaft und Energie im Rahmen des 7. Energieforschungsprogramms unter dem Kennzeichen 03EE3042 gefördert.

Großlagerprüfstand BEAT6.1 des Fraunhofer IWES - Ulrich Perrey