Sensorise SmartScrew

Simple load measurement for dynamically loaded bolts

Screw and bolt connections fasten two or more components and ensure that they behave like one part.

The connections are secured against unscrewing due to the high flank friction in the thread, caused by a well-defined preload.

The world is not static. Even in perfectly installed screws and bolts, superimposed dynamic loads can cause self-loosening or fatigue cracks. Corrosion, especially in offshore-applications, plays a major role in reducing the preload. Buildings, bridges, towers and large, complex machinery are therefore recurringly checked for failed screws and bolts.

Our integrated sensor technology measures temperature and dynamic as well as static loads on screws and bolts for better maintenance management, operational safety, and maximum lifetime utilization.

How it works

Sensor integration

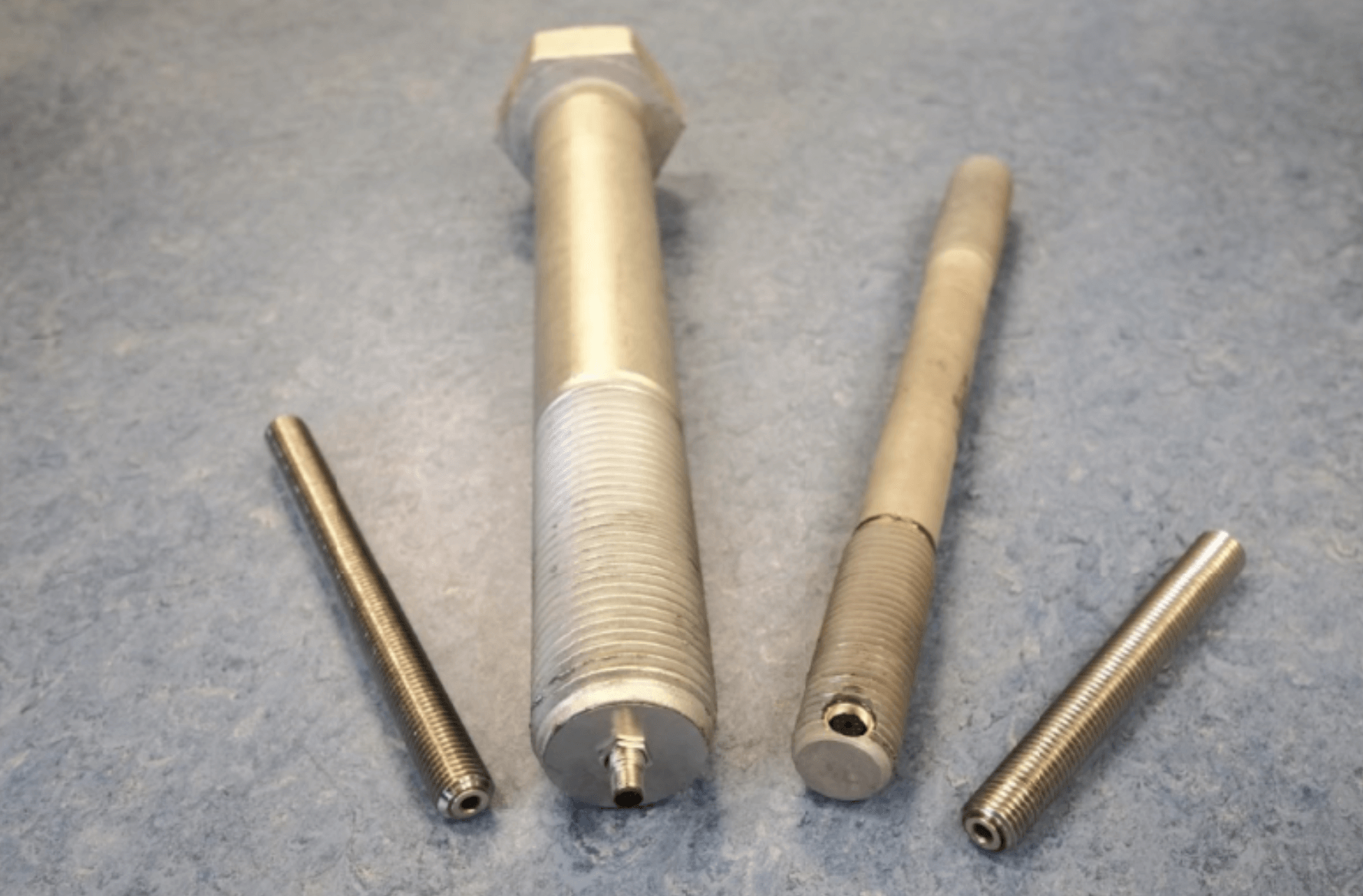

Sensorise SmartScrews are standard screws or bolts with a sensor wire, as thin as a hair, integrated into the base of the thread. This patented method utilizes existing tolerances and does not weaken the fastener.

SmartScrews exhibit the same mechanical properties as standard screws and bolts.

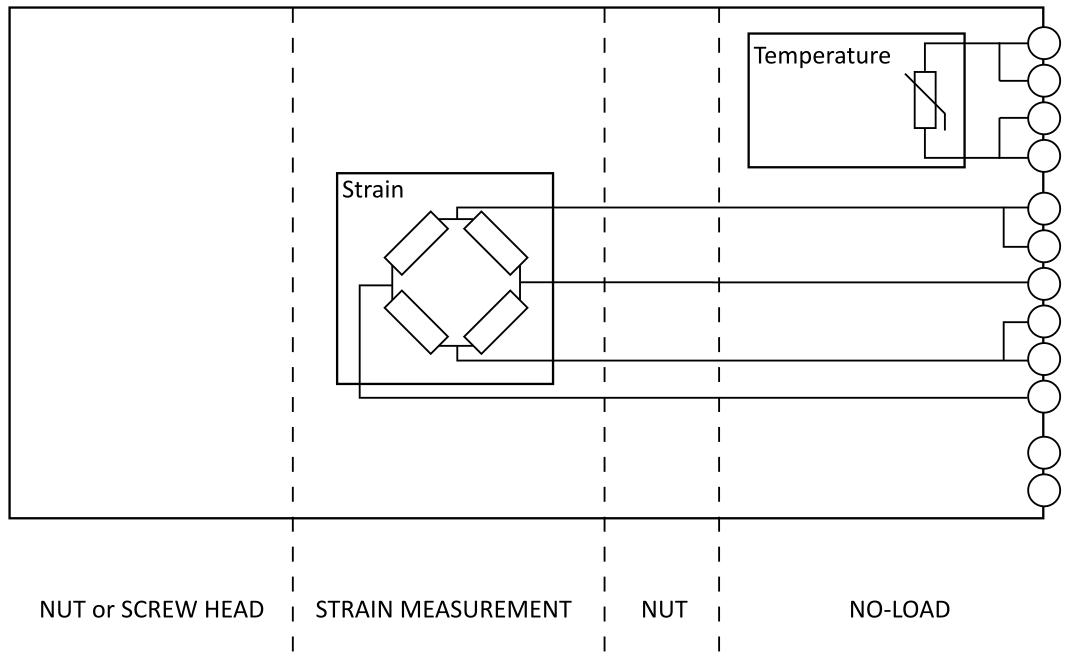

Strain measurement

The basic mechanism relies on changes in the electrical resistance of the sensor wire. When tightened, the screw elongates, and its circumference decreases. This compresses the sensor wire, thus decreasing its electrical resistance.

SmartScrews are electrically equivalent to a Wheatstone bridge and compatible with most industrial signal conditioners.

Temperature measurement

A Pt100/1000 temperature sensor is integrated to allow simple temperature compensation of the strain signal. The temperature signal provides a simple, yet important data source for dynamically loaded machinery.

Frequently asked questions

Yes. Either you provide us with the technical drawing of your fastener and the required certifications or you tell us what norm the fastener needs to conform to. You then replace the existing screw or bolt with your SmartScrew.

SmartScrews exhibit the same mechanical properties as standard screws and bolts.

Apart for a hole for the socket, which is outside the loaded part of the fastener, the mechanical design is not altered. In most applications, they can replace existing fasteners without any changes in the mechanical design, without compromising the structural integrity or load bearing capacity of the machine.

SmartScrews are installed like regular screws or bolts. They are compatible with most tools on the market.

Normally, no special training is required. Just take care not to get abrasive dirt onto the thread of the bolt or the nut as this might damage the sensor elements.

Theoretically yes, but we strongly advise against it.

The main reason is that the fastener is in an unknown state. Nobody knows how many load cycles and extreme loads it has seen. I some fields it might even be illegal to re-use fasteners that have been installed before.

The effort to uninstall, mechanically alter and reinstall will most likely cost more than manufacturing a new fastener.

SmartScrews are electrically equivalent to a Wheatstone bridge and compatible with most industrial signal conditioners. The Sensorise SmartBox makes connection, installation and calibration extremely simple.

Different socket types can be assembled. IP67 connectors are standard, IP69K is available upon request.

Standard SmartScrews are uncalibrated. This makes installation on site simpler and more cost efficient, as no attention has to be paid to which bolt goes where.

In combination with Sensorises SmartBox, calibration is carried out in-situ. This means that you enter the preload or torque from the tool as the calibration value during the installation routine.

Static load mostly is the preload that is required for proper installation of the fastener plus all loads that are constant over time. It should remain constant over the lifetime of the machine. A decrease of static load is a sign of a failing bolt connection.

Dynamic loads are all loads that are superimposed on the static loads and originate in the machines behaviour. This signal component contains valuable information about the fastener itself and the mechanical components it fixes to each other.

Try the blade bolt demo to see changing forces on a bolt effect a wind turbine.

SmartScrews measure both static and dynamic loads simultaneously.

Yes. Most signal conditioners expect a minimum bridge resistance of 350 Ohm. This leads to a minimum length of about 130 mm of thread for M42. Larger threads need a shorter minimum length and vice versa.

For good signal quality 1x D (e.g. 42 mm for M42) of stretched thread or shaft is needed as a minimum.

In most designs, 3x D is already the case: 1x D for the no-load (end) of the bolt (also recommended for tightening to yield), 1x D for the nut, a few mm for the washer and 1x D for the loaded and deformed thread. For M42 bolts thread lengths of 125 to 130 mm are common and work well.

Robust connections from M24 to M300

Standard SmartScrews are currently available for metric threads – M24 to M300. Different socket types can be assembled. IP67 connectors are standard, IP69K is available upon request.

Whitworth, trapezoidal and other screw threads are suited for the SmartScrew technology as well. Please contact Sensorise with your application.

Applications

More measurements with less effort

Strain gauges are commonly used to verify FEM simulations but are difficult to apply outside the lab. Replacing gluing strain gauges on bolts with SmartScrews enables measuring load changes of 0.1% (and less) of pre-tension.

Benefit: SmartScrews simplify data gathering, meaning more measurements with less effort.

Measure large forces

Load cells for forces larger than 1 MN are expensive and not readily available. Their height needs to be accounted for during the design phase, making it hard or sometimes even impossible to integrate them into existing structures like cranes or bridges.

Benefit: SmartScrews are normed screws and bolts, enabling simple retrofits to measure large forces in critical infrastructure without compromising its certification.